In the joint project ALK100 in 2010 between SAAB and Finnveden Powertrain utilizing our Freevalve actuators showed great results.

proven ways to improve the engine starting ability

Renewable fuel based on alcohols, like Methanol, Ethanol and Butanol, show great advantages not only in CO₂ reduction, but also in the engine’s efficiency and its maximum performance. They are however more difficult to vaporize than gasoline, which means difficulties at start up and in general when it is cold.

Hence the temperature of the air needs to be increased to be able to mix and ignite the fuel.

The Freevalve system can improve the engines ability to do this in several ways:

Add a Pre-Start heating mode for the initial cranking and first combustion.

Use one intake valve and open late with low lift for maximum turbulence and vaporization.

Use cylinder deactivation to increase the amount of air/fuel in each combustion during starting and warm-up.

Use Internal Exhaust Gas Recirculation in the following combustion cycles (use the hot residuals from previous combustion to vaporize the fuel.

Variable Compression Ratio by Miller cycle.

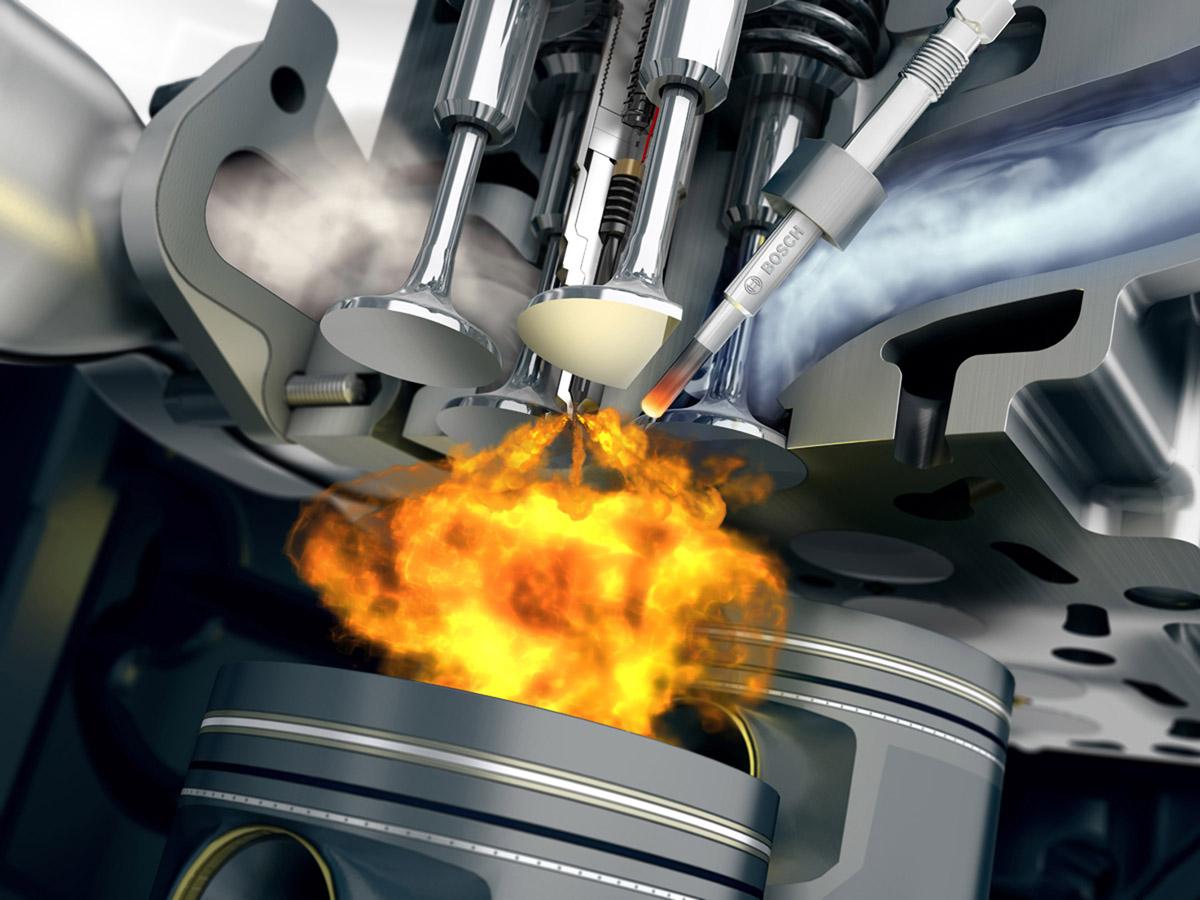

With the Freevalve system, the engine can be turned multiple times before ignition, using the piston to pump the air back and forth to the inlet in a Heating Mode cycle.

This concept was tested in the joint project ALK100 in 2010 between SAAB and Finnveden Powertrain utilizing our Freevalve actuators, with great results.

The conclusion was that the inlet air temperature increased by 30˚ C in 10 cycles which takes about 2 seconds.

By delaying intake valve opening, vacuum can be created before opening the valve, increasing the speed during the intake valve. Opening only one intake also helps in creating up to sonic flow conditions.

This can improve ability to vaporize and mixing the fuel by magnitudes.

By only operating selective cylinders, each combustion will contain more air/fuel mixture, compression temperature is increased as well as exhaust temperature.

With Freevalve system, exhaust from previous combustion can be recirculated up to the intake manifold when needed, by closing the exhaust valve and opening the intake valve during the exhaust stroke of the cylinder. Hence the hot residuals will flow up to the intake system where fuel can be injected for rapid evaporation.

This means that fuel evaporation temperature will be comfortably achieved once combustion has occurred facilitating good ignitability immediately after start.

In conventional spark ignited engines, compression is limited by knocking at full load and hot conditions. With conventional valve systems, this means that the compression ratio needs to be low enough to run full load with the most knock-prone fuel (lowest octane number allowed in the engine).

With Freevalve system, the effective compression ratio can be lowered on demand by reducing the amount of air in the cylinder before compression (Miller or Atkinson cycle).

This allows the engine compression ratio to be optimized for a high-octane number (like 100% alcohol fuels) and still be able to run full load with lower octane fuels (like Regular Gasoline). The engine will deliver less torque and power with gasoline compared to a low compression ratio engine but will be more fuel efficient.

Hence, the compression ratio for a Multifuel engine with Freevalve system is likely to be set to 15:1 or higher. Increasing compression ratio from 10 to 15 will increase temperature.

This will give very high performance and fuel efficiency with alcohol fuels and excellent start ability, while still being able to run on normal gasoline and similar fuels.

Copyright © 2022 Freevalve

Freevalve AB | Kelliehousevägen 73 | Ängelholm S-262 74 | Sweden | Registration # 556436-7141

Freevalve do not sell any products off the shelf, but we love to do development projects with customers and we constantly seek the best people in the industry to join our team.

Please contact us on the following addresses:

If you want to get in touch with the management team, click here >